Purified water systems are crucial equipment in the pharmaceutical industry, responsible for producing water that meets pharmacopoeia standards.

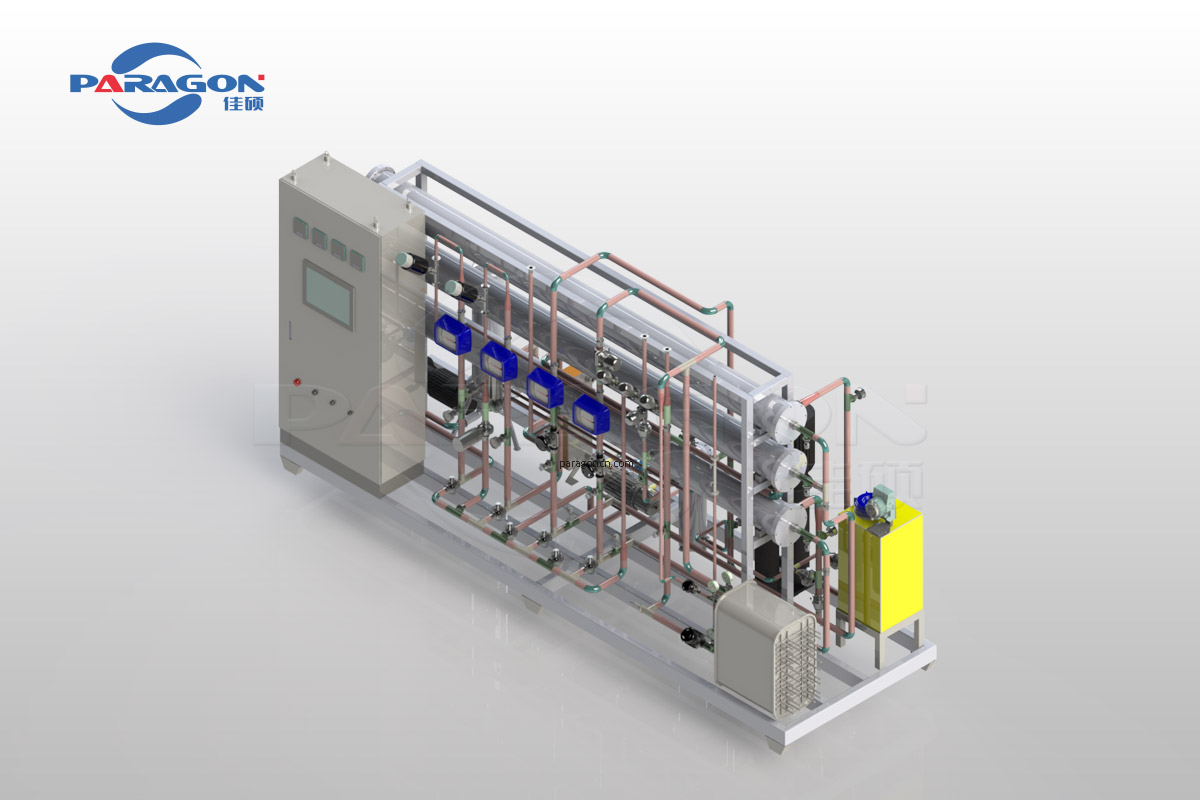

These systems typically combine multiple water treatment technologies like reverse osmosis (RO), ion exchange (IX), and UV disinfection to effectively remove impurities, microorganisms, and harmful substances from water, ensuring purity in every drop.

Whether used for drug formulation, equipment cleaning, or as feed water for Water for Injection (WFI) systems, purified water systems ensure stable water quality, meeting the most stringent needs.

Parameter

| Parameter | Description |

| Treatment Technology | Reverse Osmosis, Ion Exchange, UV Disinfection |

| Water Quality Standard | Meets USP, EP, JP, and other pharmacopoeia standards |

| Water Output Capacity | Customized based on needs (e.g., 1000 L/h, 5000 L/h) |

| Power Requirements | 220V/380V, 50Hz/60Hz |

| Control Method | PLC control with touch screen HMI |

| Hygienic Design | cGMP-compliant, easy to clean and maintain |

Application

Purified water preparation systems are widely used in industries like pharmaceuticals, food and beverage, and cosmetics, mainly for drug formulation, equipment cleaning, and container rinsing, ensuring that every product meets quality standards.