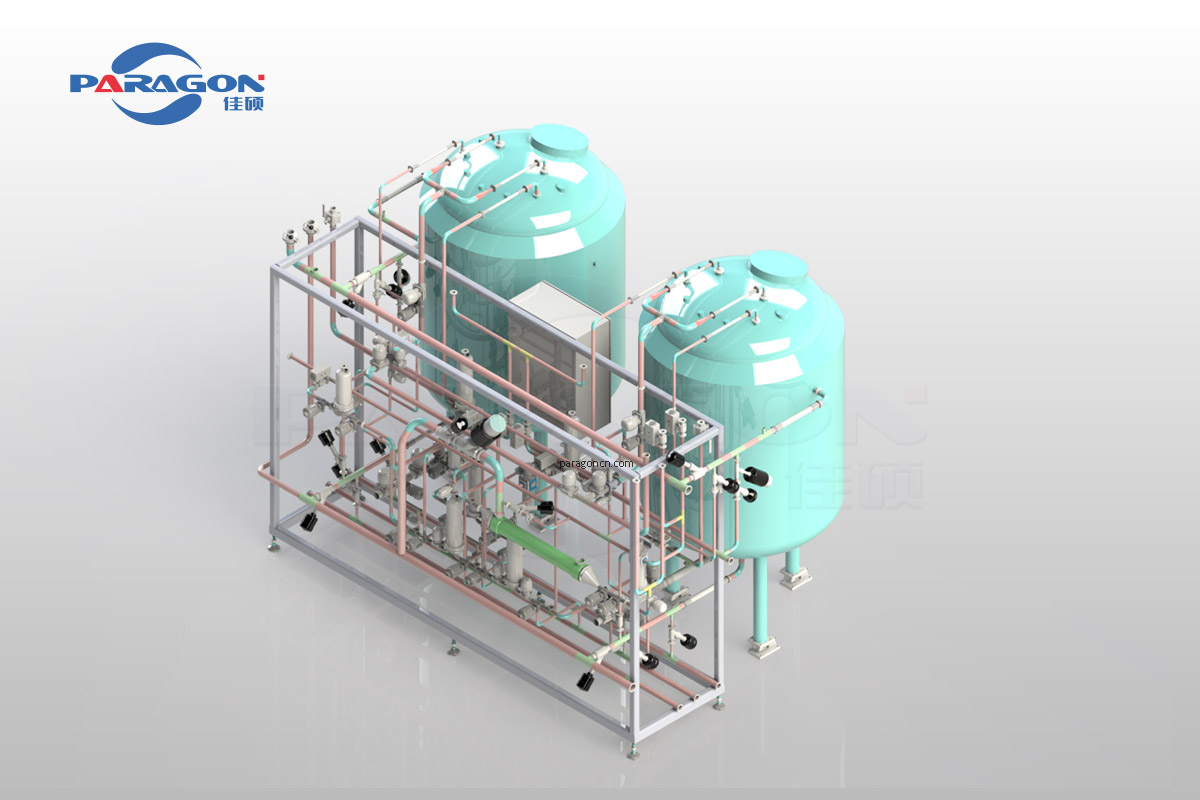

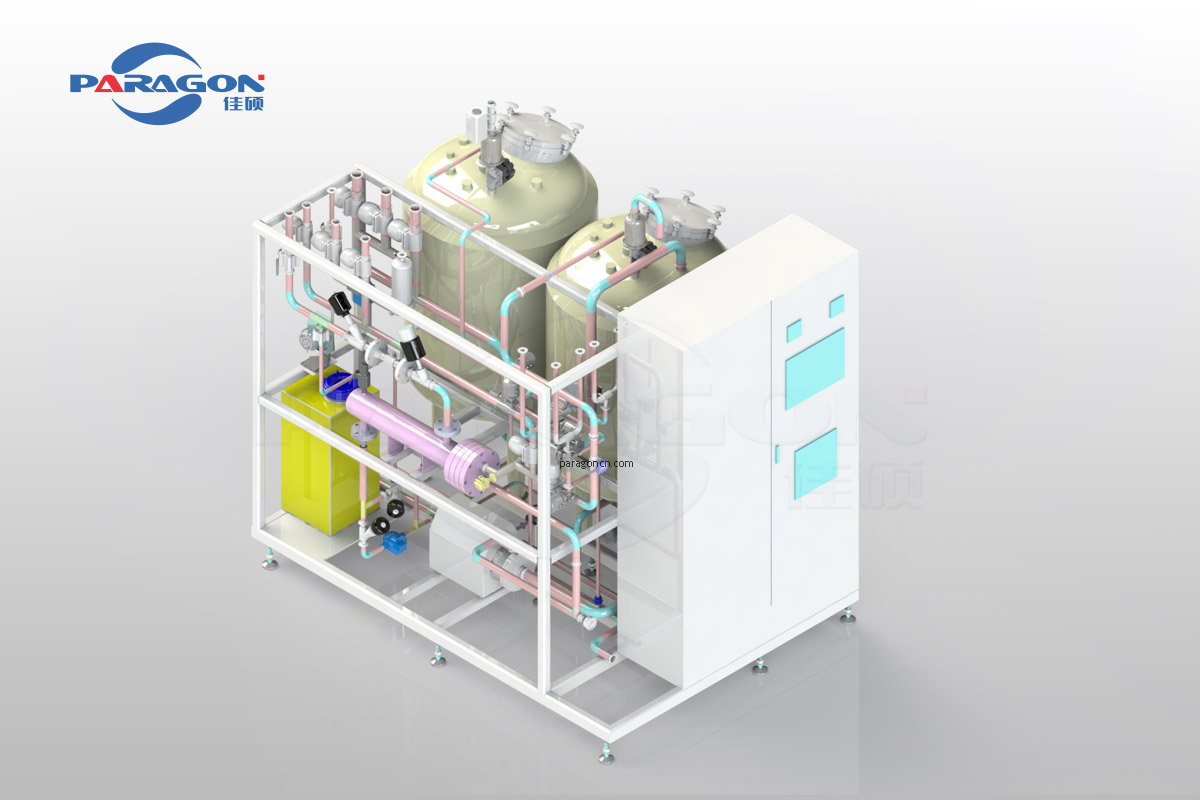

Sanitary vessels are essential equipment in modern pharmaceutical, food, beverage, and cosmetic industries. Typically made from stainless steel, these vessels meet stringent hygiene standards, making them suitable for a variety of production and storage environments.

Designed for easy cleaning, maintenance, and sanitation, these vessels help avoid contamination risks. Whether for storing solutions in pharmaceutical production, mixing raw materials in food processing, or handling formulations in cosmetics, sanitary vessels provide an efficient and safe environment for storage and processing.

Application

Sanitary vessels are widely used in industries such as pharmaceuticals, food and beverage, and cosmetics, especially in processes like liquid storage, mixing, heating, and cooling. They provide an efficient, contamination-free environment, ensuring every production step meets quality standards.

| Parameter | Description (English) |

| Material | High-quality stainless steel, FDA and cGMP compliant |

| Capacity | Customized based on needs (e.g., 100L, 500L, 1000L) |

| Design | Hygienic design, easy to clean and sanitize |

| Temperature Range | -20℃ to +150℃ (customizable) |

| Pressure Rating | Suitable for low to medium pressure applications |

| Certification | Complies with FDA, cGMP, CE, and other certification standards |