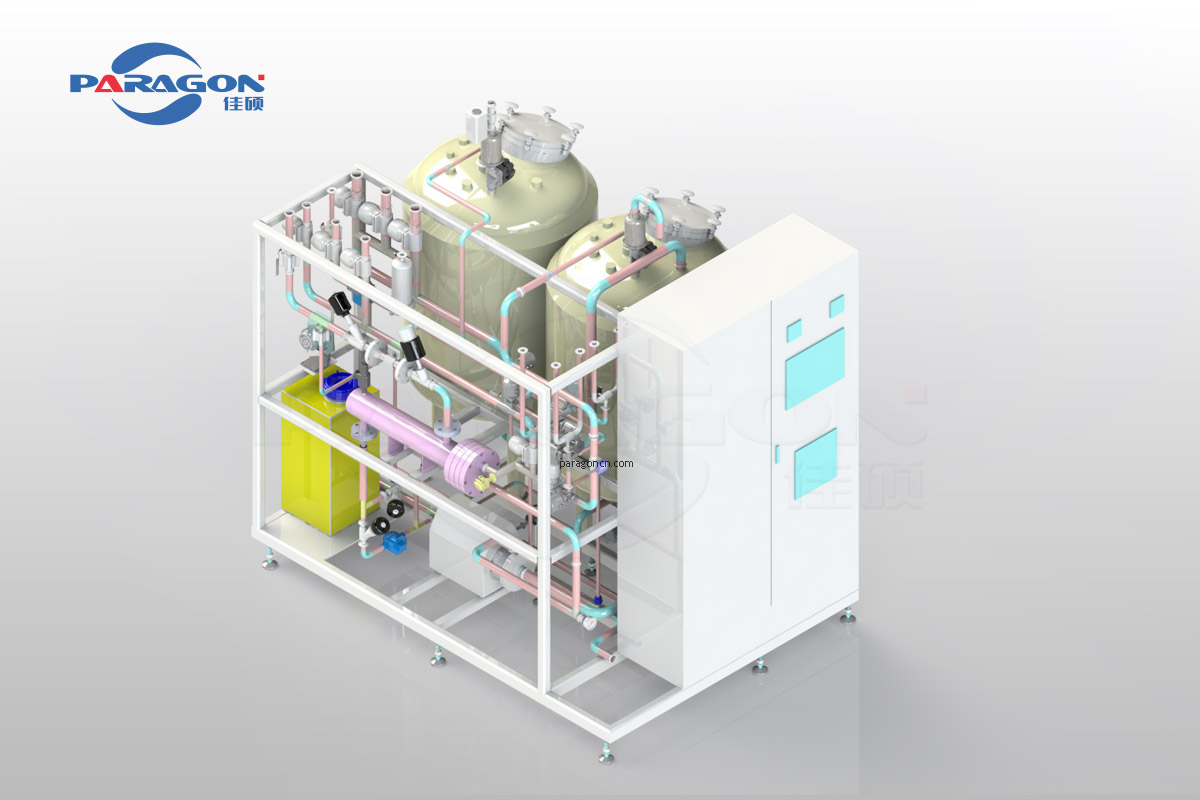

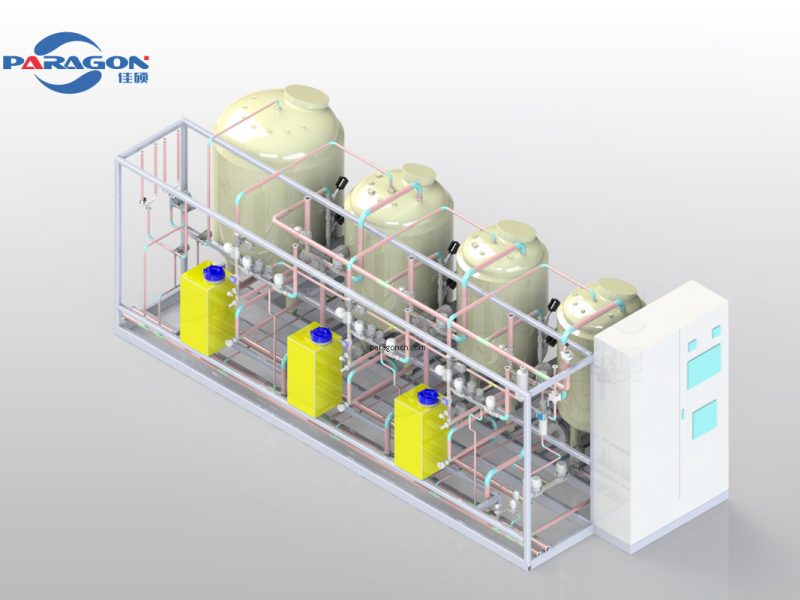

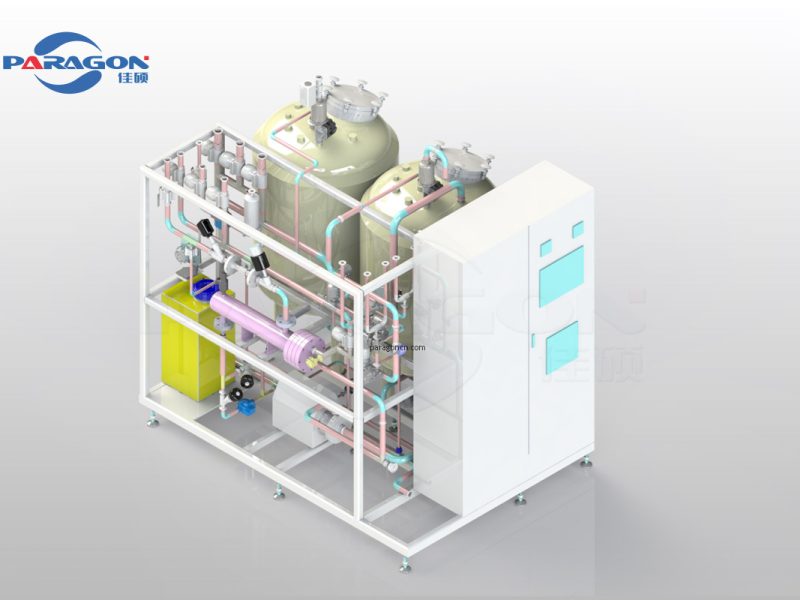

Our CIP workstations offer fully automated cleaning for solution mixing systems. Available in various forms, including mobile CIP trolleys, single-tank, double-tank, and multi-tank workstations, our CIP stations can clean the target equipment and perform self-cleaning and self-sterilization.

The system features a 3D and modularized design and elegant appearance. All essential components, such as tanks, pumps, heat exchangers, filters, valves, pipes, and instruments, are sourced from top international and domestic brands to ensure quality.

The control system hardware is a widely adopted standard module, with PLC from the Siemens S7-1500 series and HMIs fr om the TP1200 Comfort series touch screens. The program design, verification, and composition follow the V-model of GAMP 5, making the software model applicable to all S7 PLC systems.

The program is optimized according to GAMP 5 standards, enhancing stability and ensuring traceability supported by the documentation system.

The system enables fully automated control of production, cleaning, and sterilization. To guarantee the consistency of the solution mixing system under various conditions, comprehensive assessments are conducted, including Risk Assessment (RA), Design Qualification (DQ), Installation Qualification (IQ), and Operational Qualification (OQ).