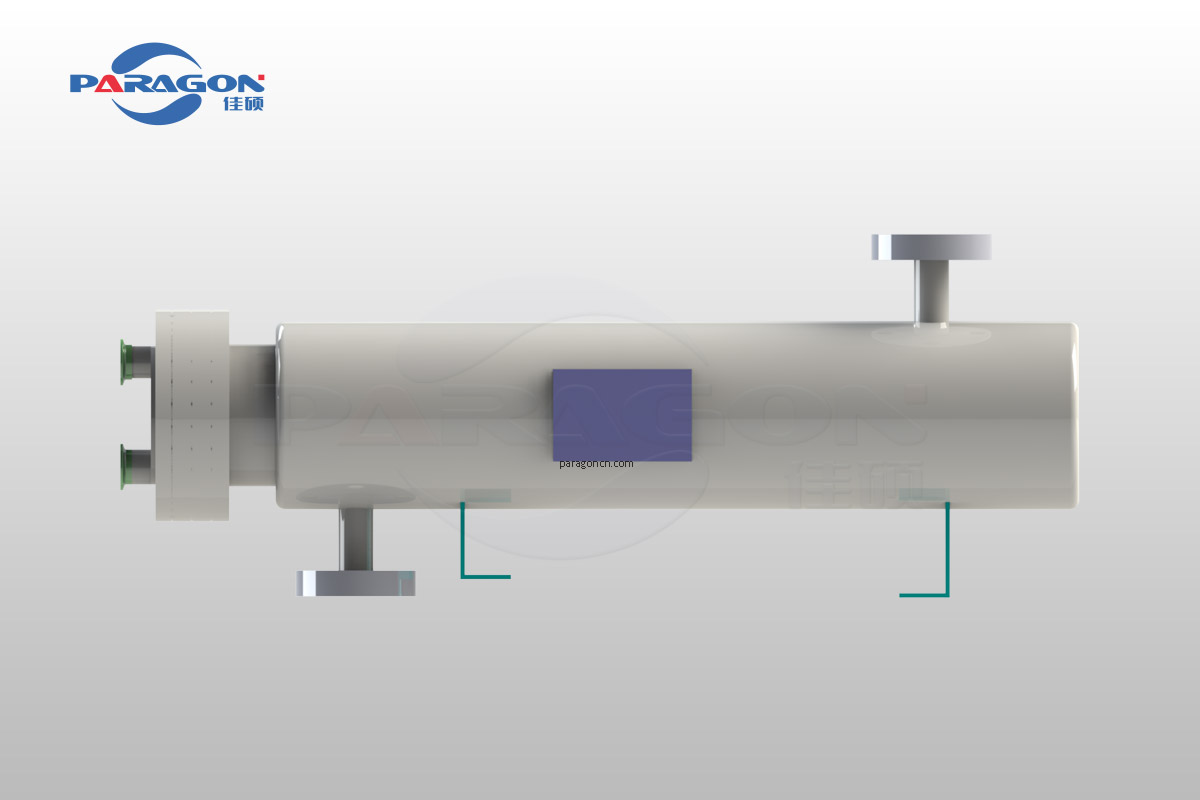

Double Tube Sheet Heat Exchanger: A Popular Choice

Double tube sheet heat exchanger stands out as one of the most popular types of heat exchangers used in industry today. Renowned for their versatility, ease of maintenance, and availability in a range of sizes, they cater to diverse applications.

It serves diverse industrial applications, making it a preferred choice across various sectors.

Key Design Considerations

In the process of choosing the ideal configuration for a shell and tube heat exchanger, factors such as temperature, pressure, and the nature of the processing fluid come into play.

- Temperature and Pressure: These parameters directly influence the choice of materials and design.

- Nature of the Processing Fluid: The type of fluid being processed impacts the materials and design of the heat exchanger.

Configuration Choices

Design options for the heat exchanger include:

- Straight or U-Tube Arrangements: Each configuration offers distinct advantages based on the specific process requirements.

- Single or Double Tube Sheets: Double tube sheets provide an added layer of security against potential fluid leakage.

Fabricated or Machined Channels: Depending on the application, the choice between fabricated or machined channels will affect performance and cost.

Application

Double tube sheets are crucial for the safe operation of many heat exchanger applications. In recent years, power plant condensers have even made use of double tube sheet designs.

And water treatment facilities use double tube sheets to prevent contamination of their treated and demineralized water from the raw water they used in their condenser steam space.

Both straight tube and U-tube style heat exchangers can utilize the double tube sheet design for added safety and security.

Straight Tube

This type of heat exchanger uses tube sheets that are either welded directly to the shell or floating inside the shell. In a welded construction, an expansion joint may be necessary to allow for differential thermal expansion between the tubes and shell.

U-Tube

As the name indicates, the tubes inside the shell are U-shaped. The tubes start at the top of the tube sheet, make a U-shaped bend, then come back to the bottom. The U-tube design does not require an expansion joint because the tube bundle is free to expand or contract.

The ability of thermal regulating equipment like heat exchangers, condensers, and immersion heaters to heat and cool substances efficiently and safely, make them an indispensable tool in industrial processes. Choosing the right equipment to fit your production operations will help greatly in ensuring your process and product quality.