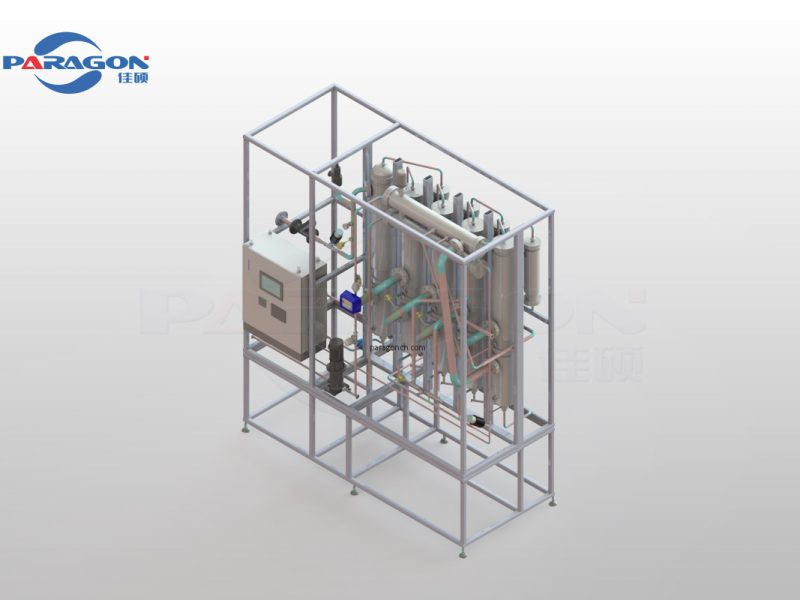

Multi-Effect Water Distiller for Producing WFI

Multi-effect water distiller produces low conductivity pyrogen / endotoxin free Water For Injection (WFI) by stage distillation process.

As the name suggests the unit consists of a series of pressure vessels in the form of columns / stills which are inter connected.

Process Overview

Boiler steam is utilised only in the first column to produce pure steam and remaining columns utilize this pure steam to produce furthermore pure steam. During this heat exchange process, pure steam condenses.

Efficient Condensation Process

Additional condensers are provided on top to condense the pure steam completely to produce WFI, which is essential for pharmaceutical production.

Maximum Heat Recovery & Cost Efficiency

The multi-effect distiller is designed with maximum heat recovery in mind, making it economical in terms of operating costs. This ensures that the plant operates at a low energy cost while still delivering purified WFI at the highest quality standards.

Application

Multi-effect water distillers is widely used in industries like pharmaceuticals, cosmetics, food, and laboratories to produce distilled water that meets strict quality standards.

Features

Capacity varies from 50 to 6,000 liters per hour

- Designed and manufactured as per ASME BPE and cGMP guidelines

- The WFI generated meets USP, EP, BP and IP standards

- Phase separation is based on falling film evaporator technology

- Specially designed and constructed to remove pyrogen / endotoxin

- Designed and constructed to achieve 100 % drain ability

- All wetted parts are made from AISI 316L stainless steel and rest are made of AISI 304 stainless steel

- All water contact surfaces are finished to electro polished to Ra < 0.4 and are crevice free

- IPC & PLC based 21 CFR part 11 complied fully automatic control panel with online printing facility

- Double tube sheet construction for the first column, where boiler steam is present

- Our compact and optimized design required minimum human interference. This means low maintenance and low operational cost

- Complete set of documentation and certificates to ensure compliance with regulatory authority. We provide DQ, OQ, IQ, FAT & SAT. Also assist client to develop PQ