PARAGON ensures a clear answer to any request related to water treatments for pharmaceutical water production and any other critical water application (e.g. cosmetics, health-care, human and animal aliments). We apply a very focalised and precise approach and a wide range of specific knowledge.

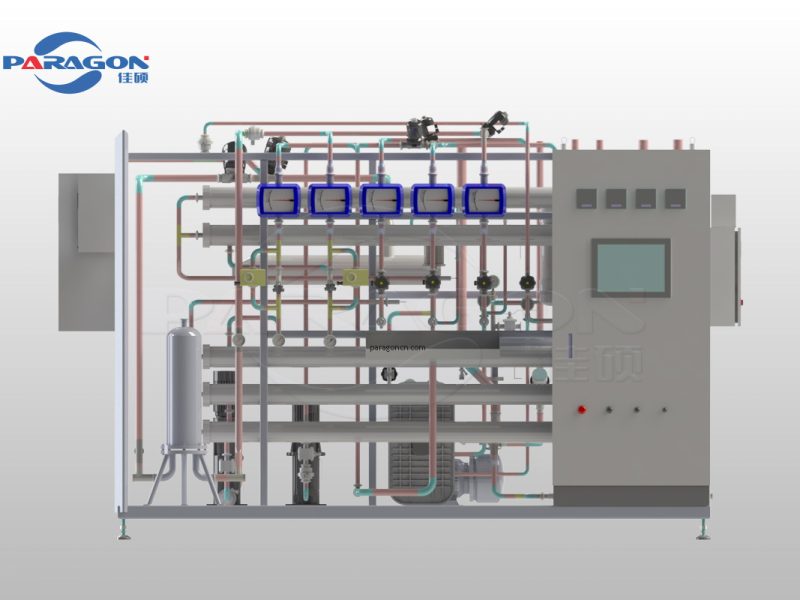

Our reverse osmosis PW systems, are designed to produce purified water (PW) and water for injection (WFI), through a number of water treatment phases, based on specific feed water’s quality and on the specified production’s necessities.

Operates through different water treatment phases, both related to the specific water quality and to the production necessities. The treatment phases which are needed to divide water from any organic substance, both with high or medium molecular weight, include:

- Sodium hypochloride dosing station for water disinfection and oxidation of organic substances, reducing the bacterial charge

- Sodium metabisulphite dosing station for neutralization and chlorine

- Double filtration system to eliminate solid substances in inlet water

- Single or double osmotic stage

- Continous Electro-Deionizer

- UV lamps

- Final sterile filtration -0,22 µm

While WFI needs downhill ultrafiltration, purified water, traditionally produced through reversed osmosis, is commonly produced through:

- Single stage RO + Electrodeionization

- Double stage RO

- Double stage RO + Electrodeionization

We customize a range of purification solution packages depending on the properties of your raw water, including RO+EDI, RO+RO, and RO+RO+EDI. Our solutions produce PW (purified water) that meets the requirements of Chinese,

EU, and US pharmacopeias.

The system features modularized production with a compact and efficient structure, making it easy to operate and maintain while requiring minimal space.

The system has a dual-pipeline PW supply with a unique internal circulation mode, ensuring better microbial control.

The system has a self-cleaning feature that enhances membrane performance.

The closed-loop pasteurization mode enables thorough sterilization and precise temperature control.

It also extends membrane lifespan and ensures consistent water purification performance.

Our equipment has a PLC control system and an operation system compliant with GAMP5 and 21 CFR PART 11 respectively.

Various communication modes are also provided.

You are free to choose from digital and paper recording devices for real-time logging of key parameters.