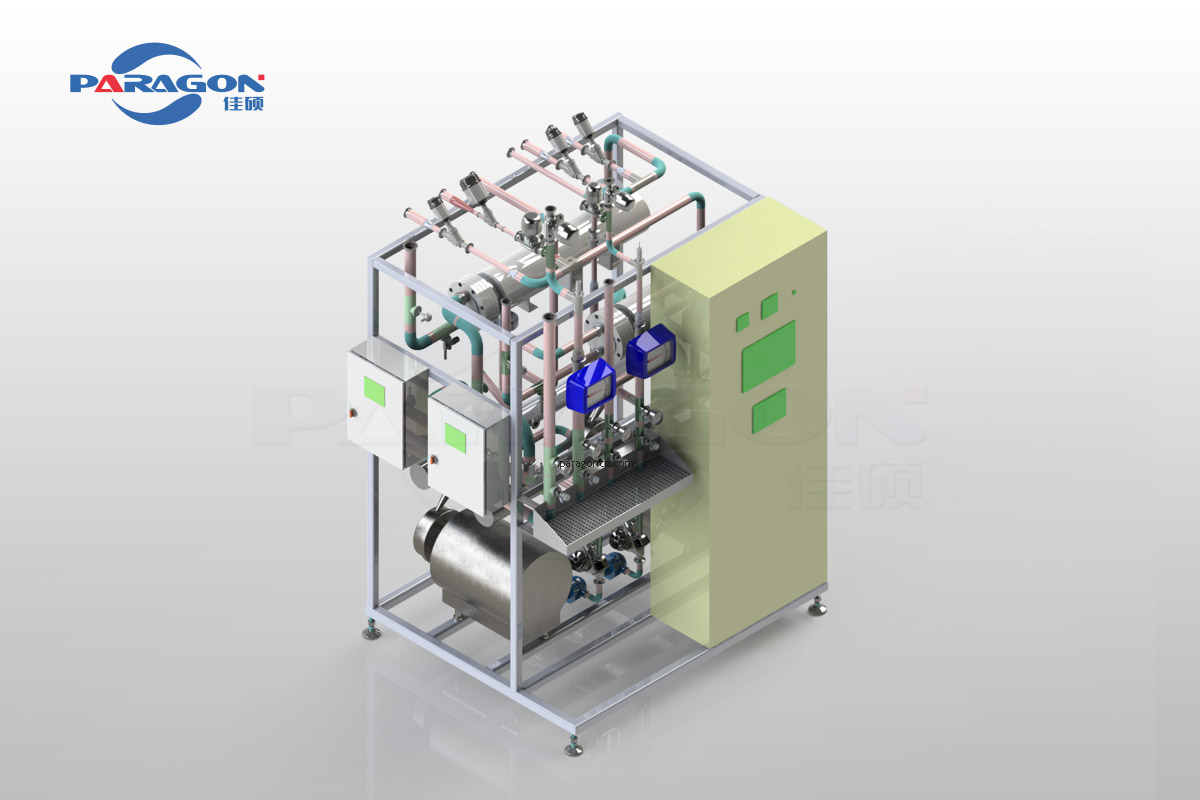

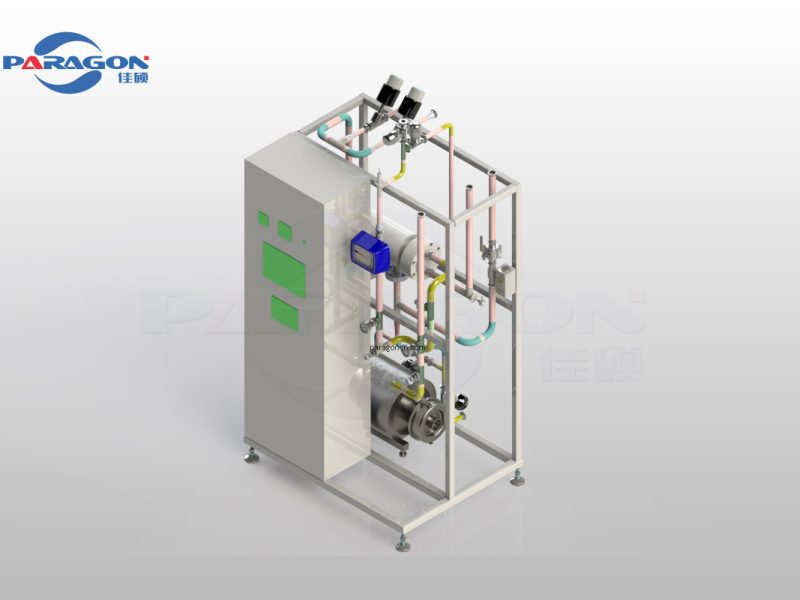

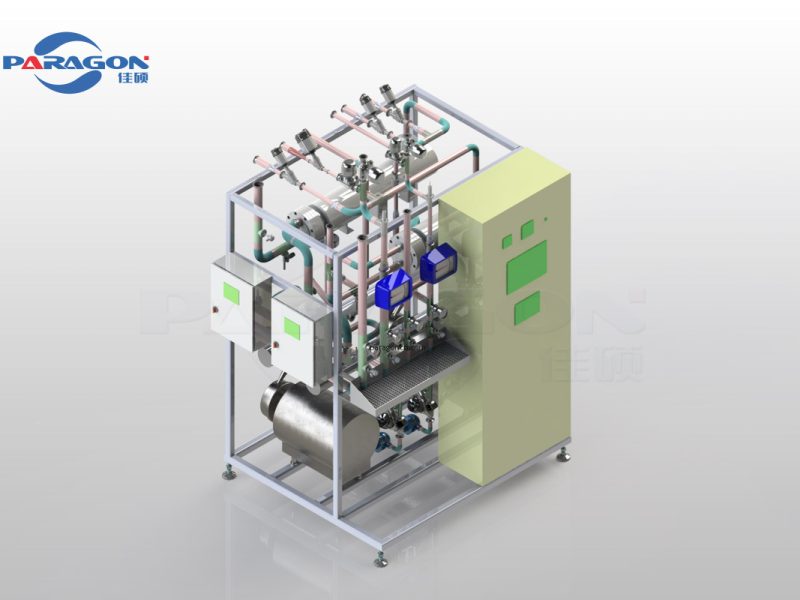

PW / WFI Distribution System in Pharmaceutical Industry

PW / WFI distribution system is required to distribute the PW /WFI within the pharmaceutical factory. The system ensures stringent quality parameters of Pharmaceutical / Biotech industry.

Closed Loop System for Water Integrity

The distribution system is a closed loop system. Closed loop system ensures integrity of the purified water.

This design prevents contamination and ensures the water remains free from harmful substances.

Monitoring & Control of Distribution Parameters

The entire Storage & Distribution System parameters are monitored & controlled with the help of instruments & equipment mounted on Distribution Skid.

This ensures the water distribution system operates smoothly, maintaining high-quality standards.

Reliable Components for Long-Term Stability

Primary components, such as pumps, heat exchangers, valves, pipes, and instruments, are sourced from world-renowned brands to ensure long-term stable operation.

These high-quality components are selected to ensure the long-term stable operation of the entire distribution system.

Features

The PW / WFI SKID, designed by 3D software, has a modularized, compact, and efficient structure that is easy to operate and pleasant in appearance. We also provide customized modules depending on your needs.

- IPC & PLC based fully automated plant complies with 21 CFR Part 11 & GAMP 5

- Fully drainable sanitary pumps are selected to maintain minimum velocity of 1.2 m/s in the return line at peak load consumption

- Distribution skid is provided with instruments to monitor parameters like temperature, conductivity, pressure, flow rate, velocity and also TOC count

- Distribution piping is designed for minimum dead leg criterion of < 1.5 D

- Distribution Loop tubes are semi seamless tubes as per ASTM A270

- All contact parts MOC is AISI 316L Stainless Steel and electro polished to less than 0.4 Resurface finish and Non-Contact parts are AISI 304 Stainless Steel

- The Distribution loop is designed for 100% drain ability by maintaining the minimum slope of 1:100

- All weld joints in the loop are orbital welded using high purity (99.99%) argon gas and can be inspected by boroscopy machine

- Complete set of documentation and certificates to ensure compliance with regulatory authority. We provide DQ, OQ, IQ, FAT & SAT. Also assist client to develop PQ