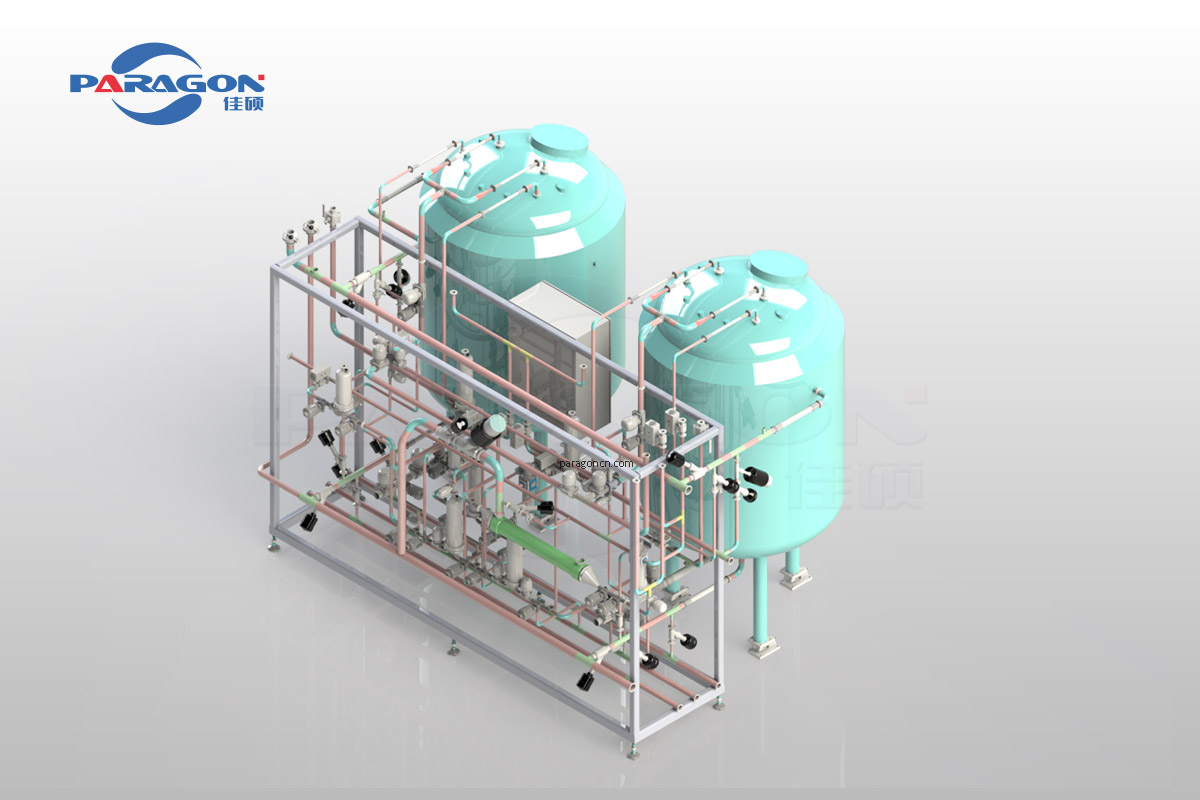

The Liquid Oral Manufacturing Plant is also known as Syrup Manufacturing Plant.

The sugar and water are loaded to the Sugar Syrup Vessel either manually or with the vacuum system. Here sugar syrup is prepared using stirrer & electrical / steam heating at required temperature.

If required activated carbon can be used to make sugar syrup crystal clear. Sugar syrup is transferred to manufacturing Vessel by vacuum or by pump through basket filter.

After processing in manufacturing vessel the product can be homogenised with the use of homogeniser. Homogeniser has inbuilt pumping facility which can provide desired multiple passes in recirculation mode.

Finally the transfer pump discharges the final product to the storage vessel through zero hold up filter press.

Features

Available in various batch capacities from 50 liters to 20,000 liters

- Complete plant is designed & manufactured as per cGMP & ASME BPE guidelines

- All vessels are vacuum rated and hence can be sterilized

- Bottom entry stirrer can be provided to restrict overall height

- All Tanks are provided with necessary accessories for reliable performance

- Pre-mix Vessel can be provided if process demands

- IPC & PLC based 21 CFR part 11 complied fully automatic control panel with online printing facility

- Working platform and ladder with railing in AISI 304 stainless steel

- All connecting pipelines, fittings, valves and contact parts are of AISI 316 stainless steel and are electro-polished and crevice free

- Sugar Melting Vessel and Manufacturing Vessel can be provided with jacket or limpet coil for steam heating. If required, provision of electric heating can also be provided. All Vessels are provided suitable rockwool / glass wool insulation and AISI 304 stainless steel cladding

- Loadcell is provided for volumetric measurement

- Spray ball is provided in all vessels for online CIP

- Complete set of documentation and certificates to ensure compliance with regulatory authority. We provide DQ, OQ, IQ, FAT & SAT. Also assist client to develop PQ